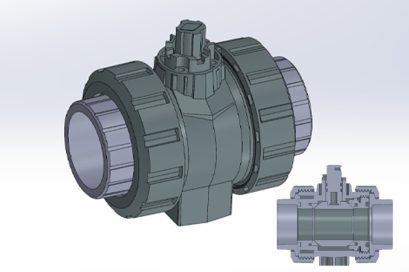

Detailed modelling is the phase wherein we create a exact scale model with detailed fittings and component assembly as per the final product. Once we have a properly designed surface model of the product, we use that class A model to convert to Class B model, having details of component placing, fitting such as screw, threads, mounting bosses, flange, locking snaps etc. We also consider mold feasibility parameters such as Draft lines, undercut analysis, Parting position, Thickness uniformity while material filling, Gate design for mold, Core Cavity feasibility, etc. This gives us an exact idea of operation in developing the product die and the Manufacturing feasibility of the product. It also gives clarity of sourcing precise components with accurate fitting. Once we assemble all components, we also get the final product physical visualization compared to proposed design.